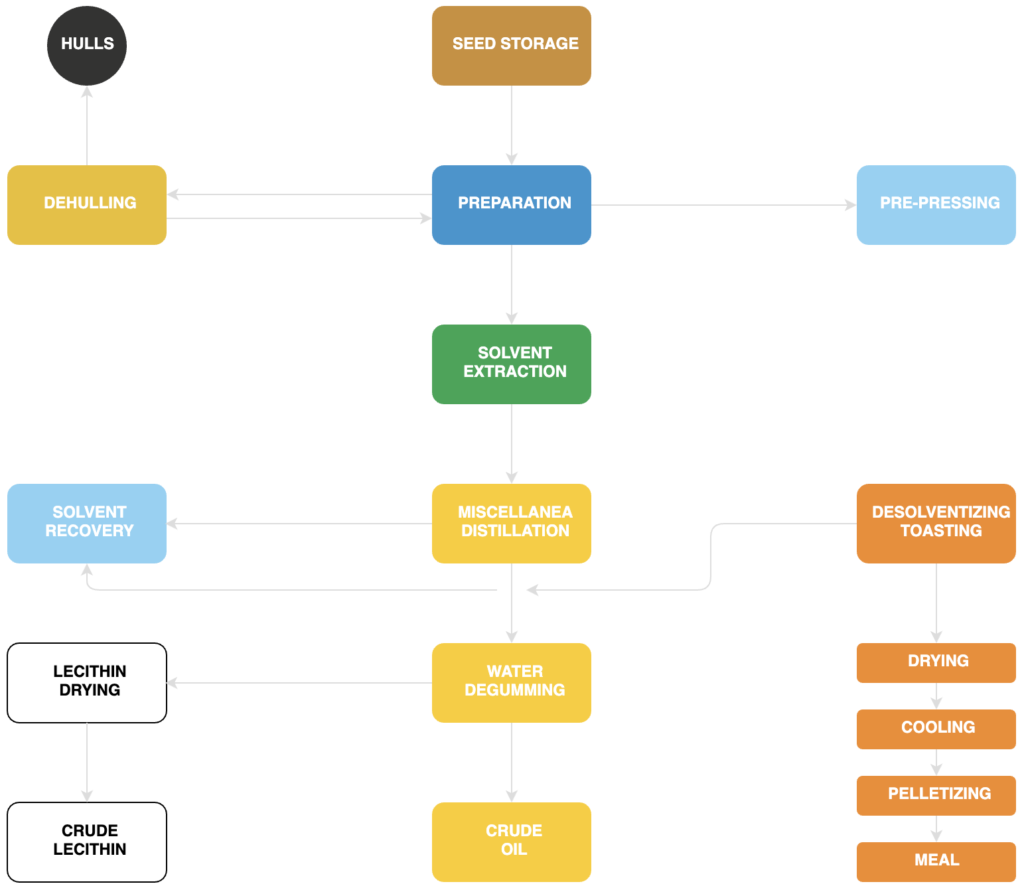

OIL EXTRACTION PROCESS

CMB is able to supply two different types of extractors: belt extractor and two-stage belt extractor Swivel extractor: double bridge

Solvent extraction

This process includes

- Seed Extraction

- Meal Desolventizing and Toasting

- Solvent Evaporation and scrubbing

CMB is in a position to supply two different types of extractors:

Belt extractor & double stage belt extractor

Designed to improve the performance of conventional continuous rotary extractors consisting of multi-rotary cell compartments and double floor where material to be extracted is turned out when passing from second to first bed of material to be extracted .

Process design principles and advantages:

- Total counter-current flow

- Level variation for best performance

- Belt speed control

- Self-cleaning screen plates for heavy duty and long life

- Optimized percolation and soaking by maintaining a miscella bath over the product

- Optimized extraction stages, each with several miscella inlets

- Compact design, workshop assembly, easy on-site delivery and erection

CMB is able to supply two different types of extractors

Meal desolventizing and toasting

Here, too, CMB can provide with two different options:

- Desolventizer – Cooler

- Desolventizer, toaster, dryer and cooler

The common desolventizer consists of a set of superimposed horizontal trays.

The download flow of the meal from one tray to the next is provided by rotating arms.

An amount of live steam is injected in the various compartments to remove the solvent from the meal completely. This machine is also equipped with dryer-cooler plates.

The DTDC (Desolventizer – Toaster – Dryer – Cooler) allows to obtain desolventizing-toasting-drying and cooling of de-oiled meal. Normally it is used for soybean meal.

Advantages are the following:

- High desolventizing efficiency due to the special trays design

- Steam savings due to special level control system on each tray

- Very low residual solvent content in the meal

Solvent evaporation and scrubbing

Removal of solvent from the pre-concentrated miscella is done in two stages. In the first stage (distillation) the solvent is distilled at atmospheric pressure, whereas in the second stage (stripping) it is removed under vacuum. All vents from the various units are conveyed to a pack tower scrubbing system which considerably reduces the hexane concentration going on air.

Technology for vegetable oil Plants

Oilseed Preparation

Optimization of seeds for extraction, through processes like cracking, flaking, cooking-conditioning and pre-pressing.

Oil Extraction

Top level technologies and processes to obtain excellent vegetable oils through cold pressing and solvent extraction.

Oils & Fats Refining

Processes to obtain the best products reducing to a minimum the requirements of energy and bleaching earths, floor area and labor.

Oleochemical

High quality oleochemical processes including fat splitting, fatty acids distillation and fractionation.

Biodiesel

Technologies and products particularly efficient in the biodiesel and biofuel production, obtained from renewable sources.

Special Plant

Design and realization of tailor-made plants, following every kind of customized production needs of customers.